CLADDING

Elevate your walls with our huge range of cladding options!

Designwood offers a large range of quality Australian cladding options in various materials, profiles and grades. Our aim is to have cladding suitable for every project and budget. Whether you require interior cladding or exterior cladding for your home or business, Designwood can supply customised cladding to suit. This long lasting and durable surface is the perfect aesthetic touch to any home or business.

Cladding Benefits

- Useful to affix to both steel and timber frames

- Long lasting surface

- A plethora of finishes and species are available

- Can be used in bush fire prone areas

- Great natural insulation material

- Adds a contemporary or modern design

- Lightweight and durable

What is timber cladding?

Timber cladding is the perfect natural material to affix to the interior or exterior of both homes and businesses. It is both decorative yet functional, providing structures with insulation and a natural look. As either a feature wall or on the entire exterior of your building. As Newcastle and Lake Macquarie’s timber cladding specialists, we can customise the width, species (colour), grade, finish and fastening capabilities.

Some Available Species for Timber Cladding

Designwood is a premium timber cladding supplier. With our extensive showroom located on the shores of Lake Macquarie, we proudly supply the Newcastle, Central Coast and Hunter Valley regions with the best timber cladding that Australia has to offer.

We are experts at supplying timber cladding which moulds to your exact design. Whilst both functional and aesthetic, the timber cladding options at Designwood are endless. We can also provide a custom design consultation with our Timber team to create new and exciting timber cladding ranges for your project. Whatever the quantity, species or finish, know that Designwood has the timber cladding solution to suit.

Designwood offers sustainable recycled timber cladding options. This is in line with our pledge to creating a sustainable timber supply chain.

TIMBER CLADDING APPLICATIONS

01.

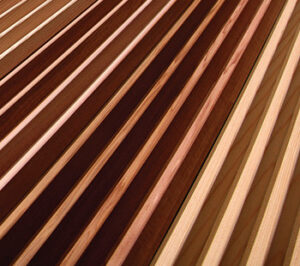

BATTEN CLADDING

Designwood offers a range of batten cladding and indoor screening options. From commercial shopping centers to offices, batten cladding is the ideal solution for creating depth into your application. Batten applications can be supplied in rough sawn, clean dressed, lightly dressed for a sawtooth look or wire brushed.

02.

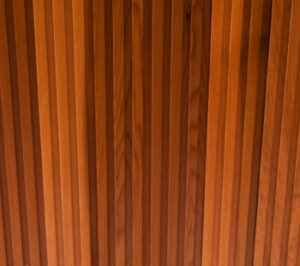

V JOINT CLADDING

Our V joint cladding options are suitable for indoor applications. This provides us with a stylish and strong method to connect.

03.

SQUARE EDGE CLADDING

Our square edge cladding is designed to be used for internal feature walls, decks, pergolas and other covered areas. This option is not as waterproof. We can supply this in 150mm or 90mm wide reclaimed wood boards. There is the option to add a batten to add external feature walls.

04.

JAPANESE CHARRED CLADDING

Our Shou Sugi Ban Refined Architectural Cladding combines the ancient Japanese craft of fire treatment with a precision milled, architectonic cladding profile. It is a complete solution for any exterior wall, offering not just the cladding but a selection of customised trims to ensure a streamline execution and a watertight result.

The timber species selected to manufacture Designwood’s Shou

Sugi Ban is ethically sourced and processed by Hurford’s

locally owned and operated facility in Queensland, Australia.

Favourably sort after for its natural qualities and unique

appearance, Callitris glaucophylla is highly durable and a

naturally termite resistant species. Applying the fire treatment

forces an additional barrier of protection against insect attack

and decay, furthermore increasing the species overall durability.

Designwood uses a modernised Shou Sugi Ban technique,

the process evenly chars the face of the board before it is

cooled and finished.

Shou Sugi Ban Refined Architectural Cladding,

is an aesthetically pleasing yet durable façade option

Clean wood is the perfect surface to affix cladding. Cladding is generally used on the exterior. For that reason, it’s likely going to experience many weather conditions in the harsh Australian environment. In Newcastle (with the sea nearby), it is important to use a coating that has both water and UV resistant.

This will help prevent degradation and structural damage from occurring. The best method of treatment is prevention. If you have a regular maintenance schedule and keep an eye out for anything out of the ordinary to ensure your cladding looking aesthetically pleasing for years to come.

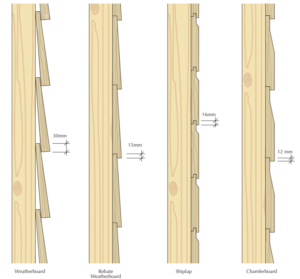

Solid timber cladding boards are available in either seasoned or unseasoned materials. Seasoned boards are characterised by being dressed, having a machined moulded face, and interlocking tongue and groove (or rebated) joint. Unseasoned boards are more likely to be rough sawn, have an unmachined face, and the absence of any tongue and groove joint. Cypress can often be supplied unseasoned, with a machined face and a tongue and groove joint designed to accommodate the expected shrinkage. This allows for shrinkage movement in-situ. The most common options are shown below:

Species used for cladding include: Blackbutt, Cypress, Tallowwood, Spotted Gum, and a mixture of species generally termed mixed hardwoods. Each can be purchased in specific grades defining natural features of the cladding.

Sarking is used to direct water that may have penetrated the cladding back to the outside. It also provides a barrier to prevent drafts, wind driven rain and dust from entering the wall cavity. Sarking must be weather proof but vapour permeable, and is often made from aluminium foil or bitumen bonded insulation. This is fixed directly behind the timber cladding.

Additional detailing may also be necessary where condensation is a concern. This occurs where there is a large temperature difference between the indoor and outdoor environments – as in very cold climates. Cavity insulation can help by reducing cold outer air from meeting warm inner air. In extreme conditions a devoted vapour barrier on the warm side of the insulation may also be necessary.

Nailing requirements also vary according to seasoned or unseasoned states. For instance, unseasoned boards must be able to shrink independently of each other. Therefore nailing through overlaps must be avoided but must still provide restraint to the inner board. Seasoned boards also should be nailed well away from edges to avoid splitting of thinner sections, or where tongue and groove or rebated overlaps occur. In addition, all board ends should pre-drilled to prevent splitting and flat head nails should be used to prevent pullout. Nails also need to be chosen to suit durability requirements and hot-dip galvanised nails are often adequate.

Installation practices must be undertaken with weather resistance in mind.

• Boards with grooves must be fixed with the groove facing downwards.

• Sealants such as mastics should be avoided.

• Butt joints between boards should be minimised to limit moisture ingress e.g. single or long lengths should be used on walls exposed to prevailing weather conditions, short lengths could be used between windows or on sheltered parts of the wall, such as under eaves and verandas.

• Butt joints should be achieved by slightly over cutting board lengths then snapping the bowed board into position. For durability, boards should be end sealed prior to installation (e.g. with paint or oil based stain).

Sources: Timber Manual, National Association of Forest Industries Ltd., Canberra. and Cypress and Hardwood Claddings, Timber Research and Development Advisory Council, Brisbane.